INTEGRATED FLOUR DOUGH TESTING SET - Y01

The Flour Testing Device and Dough Testing Device were integrated into one body to provide the working process with many advantages in laboratory atmosphere. Flour Testing Section is used for determining the resistance during the mixing against to the mixing arms depending on the flour quality by time of mixing process. The flour testing section gives the similar results as Farinograph. Dough Testing Section is used for the dough pieces weighed 150 gram, will be stretched special hooks of the equipment on 45, 90 and 135 minutes respectively. Mixing motor, dough shaping, rolling and stretching hook units can be control directly own embedded industrial touch screen PC and software. The dough testing section gives the similar results as Extensograph. All properties of the dough is measured, calculated, saved and converted PDF format.

Advantages :

- Easy to operate & robust design & multilanguage & user friendly software - Data and results can be stored on computer

- Integrated computer on the device, which makes possible to put on intranet

- Easy to update of software with remote access control

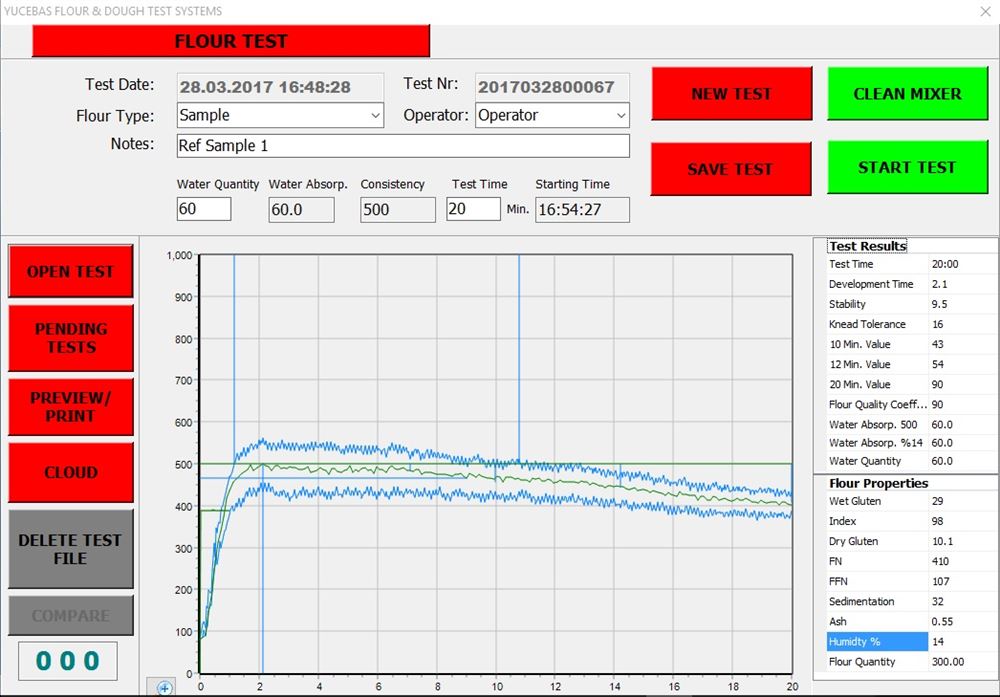

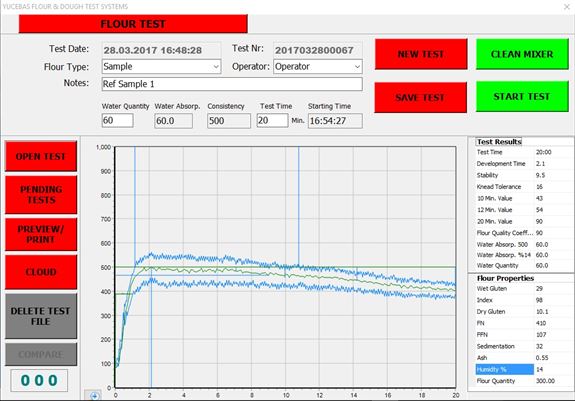

Flour Testing Section can be determine :

- Water Absorbtion Capacity (%) - Dough Development Time ( Minutes )

- Dough Stability ( Minutes )

- Knead Tolerance Index

- Softening Degrees (10th, 12th, 20th)

- Flour Quality Coefficient (FQC)

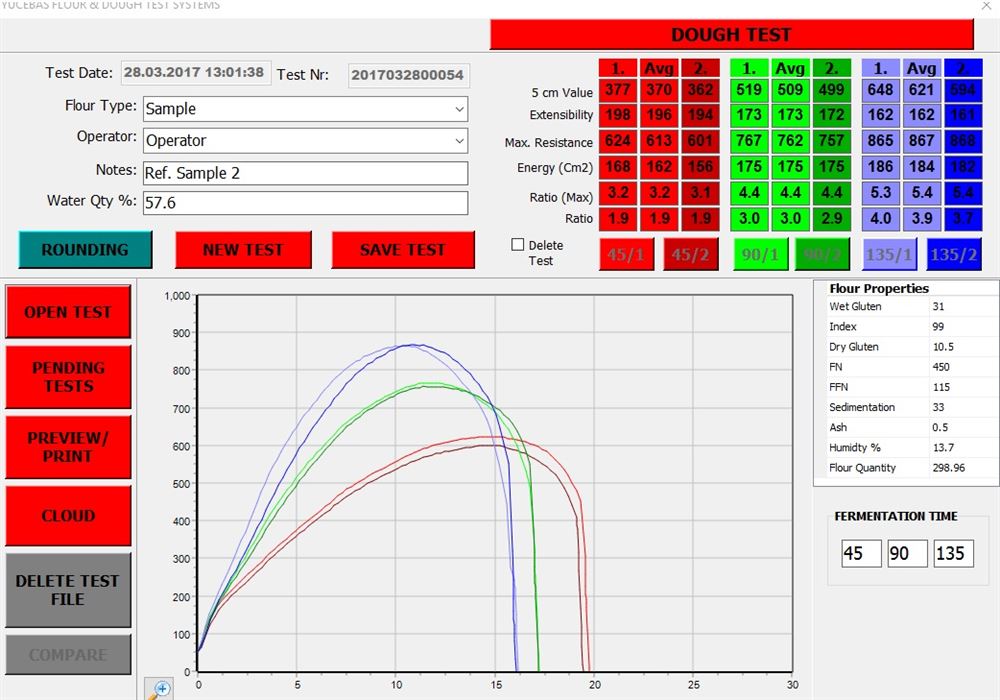

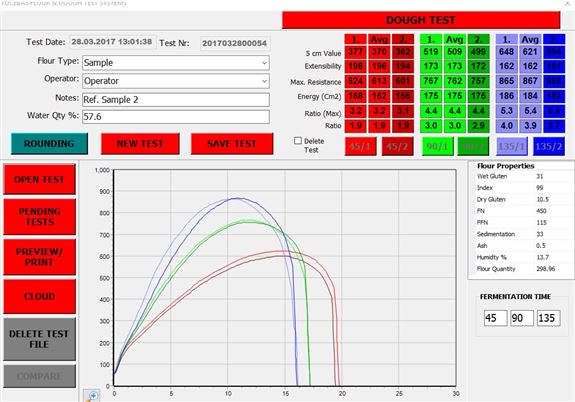

Dough Testing Section can be determine :

- Resistance of 5 cm ( R5 )

- Maximum resistance ( Rmax )

- Elasticity ( mm )

- Energy ( cm2 )

- Ratio Max

Technical Specifications:

Dimensions (H x D x W): 710 mm x 550 mm x 1220 mm

Energy: 220 V, 50 - 60 Hz

Net Weight: 200 Kg

Mixer: 300 g

Speed of Dough Shaping Unit: 83 ± 3 min-1

Speed of Dough Rolling Unit: 15 ± 1 min-1

Speed of Stretching Hook: 14,5 ± 0,5 mm/s